SERVICE BLOWER

SYSTEM Pressure FAN ? BLOWER?COMPRESSOR?

Firstly, we’d like to explain air machine types. Fans, blowers and compressors are differentiated by the method used to move air or gas, and by the system pressure they must operate against. The term “fan” and “blower” are often used interchangeably, but strictly speaking, fans are used for low pressure applications less than 10kPa, blowers are used under pressure ranges between 10kPa and 100kPa, and compressors are used for high pressure applications over 100 kPa.

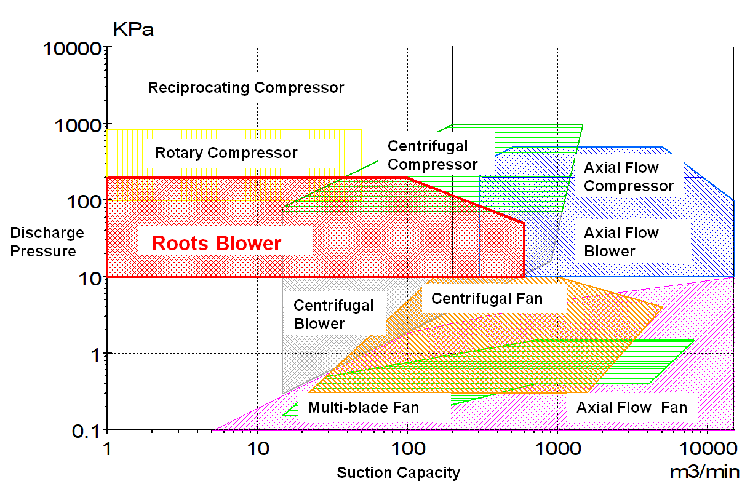

Performance of Air Machine

This diagram shows performance ranges of air machines. The vertical line indicates pressure and the horizontal one represents suction capacity. The pressure ranges of Roots blowers are between 10kPa and 100kPa in a single-stage blower, and the pressure between over 100kPa and around up to 200kPa can be available in two-stage blower. In fact, up to 225kPa can be available with ITO’s two-stage blower.

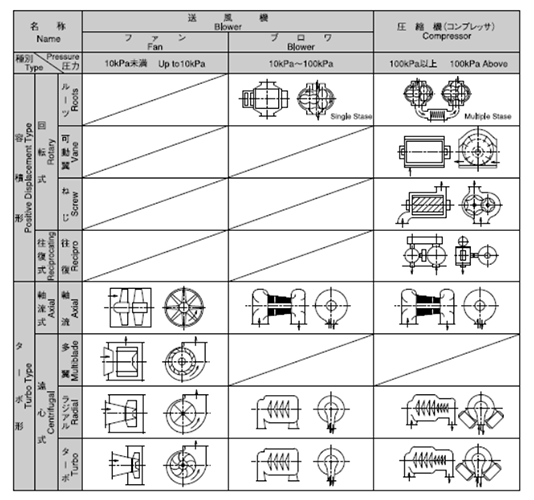

Air Machine Type

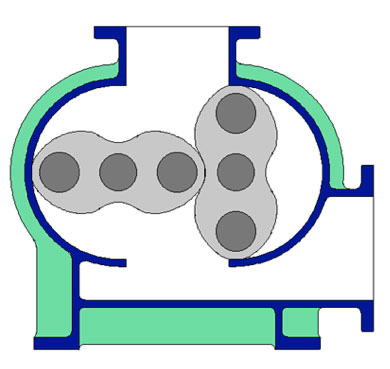

This diagram shows the types of air machines. Broadly, there are two types; positive displacement type and turbo type. Positive displacement types are divided into the two types; rotary type and reciprocating type. Besides, rotary types are categorized into the three types; Roots type, sliding vane type and screw type. Our mainstream products fall into Roots-type positive displacement rotary blowers. We call them Roots blowers for short.

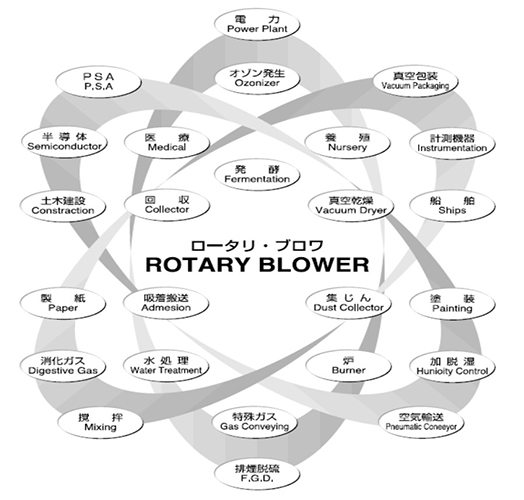

Application of PD Blowers

If constant airflow and clean, 100% oil-free air are needed for production process, PD Blowers are the best choice. In fact, PD Blowers are used in many plants for various applications such as FGD, pneumatic conveying, PSA, wastewater treatment, and so on. Among these applications, we’d like to introduce some of them.

Siamito engineering co.,ltd

Siamito engineering co.,ltd